0536-3813551

1

Maintenance and maintenance of mud pump

2018-05-21 ꄘviews:

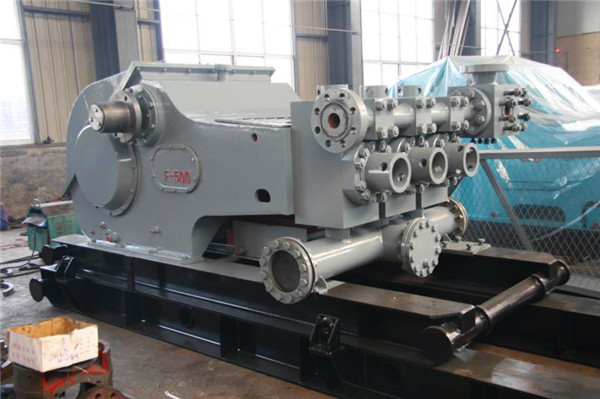

Mud Pump (Mud Pump) is a kind of broad Pump of a popular concept, different regions, habit, eventually Pump type does not involve, small make up have Mud Pump is one of the most significance type Pump: used in the field of oil drilling Mud Pump. In fact, sewage pumps, slurry pumps and other non-clear water pumps and mud pumps are also commonly used in terms of calling.

A mud pump is a machine that carries mud or water to the hole during drilling. Mud pump is an important part of drilling equipment.

Matters needing attention

Before starting up the mud pump, check whether there is a blockage in the inlet pipe and the outlet pipe, and whether the bearing is filled with grease before moving forward to check whether the packing is full. Mud pump shall be equipped with high pressure fresh water pump at work, will be bigger than the mud pump pressure water lose to the leakproof packing, packing for protection, mud pump rinse pump shall not be shut down at work, otherwise, will make the seal parts of rapid wear. The gap between the impeller and the guard plate is reasonable and has a great impact on the life of the mud pump. Gap is unreasonable, vibration and noise when the pump is running, flow components damage quickly, thus replacing the impeller and make clearance should be paid attention to meet the requirements of the drawings, gap adjustment, can by the adjusting screw on the rear bearing body. The allowable suction of the mud pump is determined when conveying water, and the influence of mud on the suction capacity should be considered when pumping mud.

maintenance

The construction department shall have special maintenance personnel responsible for the maintenance and repair of the construction machinery. Regularly inspect and maintain the mud pump and other machinery, and solve the problem as soon as possible so as not to cause shutdown. Attention should be paid to the size of sediment particles during construction. When the granule is large, it is necessary to check the vulnerable parts of the mud pump so as to repair or replace them in time. The vulnerable parts of the mud pump are mainly pump shell, bearing, impeller and so on. Adopting advanced anti-wear measures to improve the service life of vulnerable parts can reduce the input of engineering and improve production efficiency. Spare parts should be prepared for replacement in time.

hotline:

+86-0536-3813551

Web:en.qzmudpump.com E-mail:info@qzmudpump.com

Technical support:Changxun